Demold Faster, Reduce Costs, and Ensure Quality

Our electrical resistivity and temperature sensors allow precasters to demold faster, reduce production costs, and consistently ensure high-quality products through precise, real-time monitoring

Proudly trusted by

Monitor Early Stages of Concrete

DPH uses our sensors to monitor early-stage resistance in precast concrete. Learn how Sensytec’s advanced technology provides crucial data that helps optimize the construction process and ensure the quality of the final product.

We help our customers improve their operations with reliable concrete performance data

Expedite Demolding Times

Reduce Rework & Scrap

Improve Mix-Designs & Cut Material Costs

Enhance Labor Efficiency

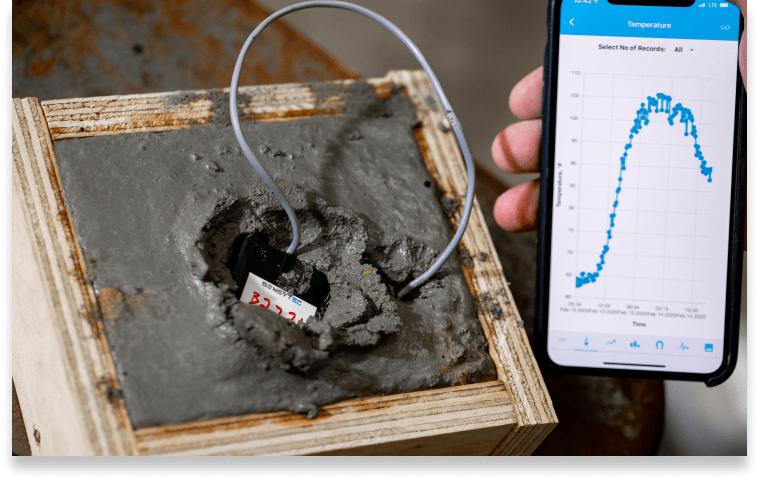

How it Works

STEP 1

Turn on sensor & place in probe in concrete

STEP 2

Sensor reads and transmits resistivity and temperature data

STEP 3

Pour as usual and wirelessly collect concrete data via mobile devices

STEP 1

Turn on sensor & place in probe in concrete

STEP 2

Sensor reads and transmits resistivity and temperature data

STEP 3

Pour as usual and wirelessly collect concrete data via mobile devices

Case Studies

Con-Fab: Transforming Prestressed Concrete Product Manufacturing

Con-Fab, a leading manufacturer of prestressed concrete products, is at the forefront of supplying essential components for infrastructure...

Enhancing Precast Manufacturing with DPH

In the concrete manufacturing and infrastructure industry, precision, efficiency, and continuous improvement are not just goals—they are necessities.

PC Solana – Precast

At a glance, Facing material and labor shortages, the customer sought ways to cut cement usage and boost...

Let us know how can we help?