Choosing Excellence: What to Look for in a Concrete Sensor

Developer

May 21, 2024

Choosing Excellence

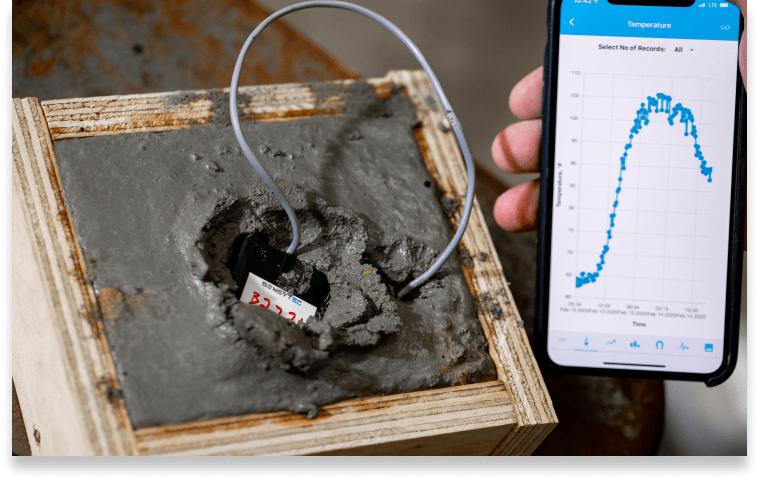

Concrete sensors are bringing about a revolution in the construction sector by offering real-time data that improves project quality and efficiency. But with so many different types of sensors out there, picking the best one can be difficult. To make sure you make the right choice, this guide will help you learn what to look for in a concrete sensor.

Accuracy and Reliability

Precision in Measurements

Accuracy is paramount when selecting a concrete sensor. The sensor should provide precise measurements of critical parameters such as temperature, humidity, and maturity. This ensures:

Quality Control:

Accurate data helps maintain optimal curing conditions, enhancing the strength and durability of the concrete.

Consistency:

Reliable sensors provide consistent data, reducing the risk of errors and ensuring the concrete meets specified standards.

Robust Construction

Choose sensors built to withstand the harsh conditions of a construction site. Look for features like water resistance, dustproofing, and durability to ensure they can operate effectively in various environments.

Data Accessibility and Integration

Real-Time Monitoring

Select sensors that offer real-time monitoring capabilities. This allows for immediate access to data, enabling prompt decision-making and timely adjustments to the curing process.

Easy Integration with Software

The sensor should seamlessly integrate with your existing project management and data analysis software. Look for sensors that offer:

User-Friendly Interfaces:

Intuitive dashboards and easy-to-read data displays.

Compatibility:

Ensure the sensor is compatible with widely used software and platforms in the construction industry.

Data Export:

Ability to export data in various formats for comprehensive analysis and reporting.

Battery Life and Power Efficiency

Long-Lasting Performance

A sensor with a long battery life minimizes the need for frequent replacements or recharging, ensuring uninterrupted monitoring. Consider:

Power Efficiency:

Sensors that optimize power usage for extended operation.

Battery Alerts:

Features that provide alerts when the battery is low, preventing unexpected downtime.

Ease of Installation and Use

Simple Installation Process

Choose sensors that are easy to install and configure. A complex installation process can lead to delays and potential errors. Look for:

Clear Instructions:

Comprehensive guides and tutorials for setup.

Minimal Tools Required:

Sensors that do not require specialized tools or extensive technical knowledge for installation.

User Training and Support

Consider the level of support and training provided by the manufacturer. Adequate training ensures that your team can effectively use the sensor and interpret the data.

Cost-Effectiveness

Initial Investment vs. Long-Term Benefits

While cost is an important factor, it’s essential to consider the long-term benefits of investing in a high-quality sensor. Evaluate:

Return on Investment (ROI):

The potential cost savings from improved efficiency, reduced material wastage, and enhanced quality.

Maintenance Costs:

Consider the long-term maintenance and operational costs associated with the sensor.

Trial Periods and Warranties

Look for manufacturers that offer trial periods or warranties. This provides an opportunity to test the sensor in real-world conditions and ensures you are protected against defects or

Advanced Features

Smart Capabilities

Advanced sensors come with smart features that can further enhance their utility. These may include:

Wireless Connectivity:

Enables remote monitoring and data access.

Alerts and Notifications:

Automated alerts for critical conditions, such as temperature spikes or deviations from expected curing rates.

Cloud Storage:

Secure and scalable data storage solutions for long-term data management and analysis.

Conlusion

Choosing the right concrete sensor is crucial for optimizing the curing process and ensuring the success of your construction projects. By focusing on accuracy, data accessibility, battery life, ease of use, cost-effectiveness, and advanced features, you can select a sensor that meets your specific needs and enhances overall project performance. Investing in a high-quality concrete sensor not only improves the quality and durability of your concrete structures but also leads to more efficient and cost-effective construction practices.