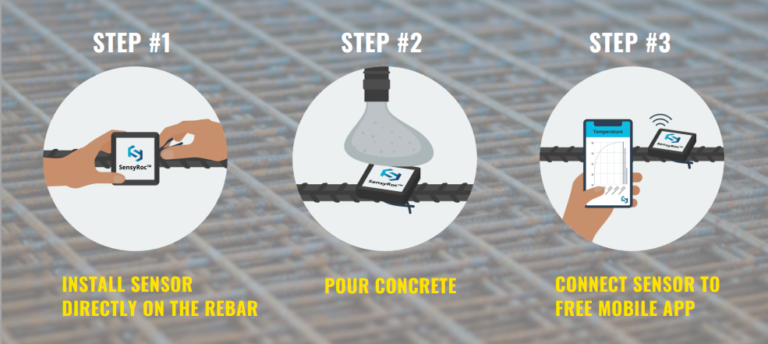

The user-friendly sensors are easily installed in the concrete formwork or rebar before pouring the concrete and this can be done by the contractor or any worker in less than a minute. Once installed, SensyRoc™ sensors continuously monitor and record the in-place temperature, concrete maturity, and strength (According to ASTM C 1074). Then, the results are automatically downloaded and annalized onsite using the free Sensytec App.

SensyRoc in Action

The image above depicts a concrete mass pour being done on the 8th floor of a 17-story building located near Katy Fwy in Houston. The General Contractor is

using SensyRoc™ sensors for early concrete strength and temperature predictions.

A DEEP DIVE INTO THE 2020 CONCRETE INDUSTRY

Almost every business has been deeply affected by the COVID-19 virus, and the construction industry has not been exempted. Since the shelter-in-place order was announced, many ongoing construction projects have been affected not only by the limited number of workers coming into work but also by shutdowns of third-party testing labs that are responsible for providing materials testing results that are crucial to keeping these projects going. Thus, during this challenging time when human interaction is limited, contractors rely on technology to ensure their projects keep moving forward.

This is when SensyRoc™ comes into play a fundamental role in the construction process. The wireless concrete sensor does not depend on key personnel like a material testing lab does for the cast and collection of concrete specimens, nor does it depend on a compressive test to provide concrete strength results.

How SensyRoc is Installed

In other words, SensyRoc™ sensors are an alternative solution to the urgent problems that the construction industry is facing today. By deploying and leveraging our technology, contractors can access critical data needed to keep their projects going, in real-time such as the in-place temperature, the strength, and the quality of the concrete in every pour without having to wait on testing results from labs.

How To Use SensyRoc™ In 3 Easy Steps

Solving Problems with SENSYTEC

We’re in the problem-solving business and this image shows it all. In a matter of a few hours, the general contractor was able to obtain the critical concrete data needed to keep this project going even during this challenging time.

By understanding, strength development in real-time, forms are coming off quicker and better decisions are being made on loading, tensioning, saw cutting, and opening concrete. We’re not in the space where we can solve it all, but SensyRoc™ sensors certainly aim to help the construction industry build structures faster, safer, and more efficient.