Proudly Trusted By Industry Experts

SensyCure™ Overview

SensyCure™ is an automatic match cure chamber that matches real concrete temperatures for accurate strength testing, faster releases, ASTM compliance, improved QA/QC, and cloud-logged data with wireless SensyCast™ and SensyHub™ integration.

SensyCure™ Match Cure Benefits

Faster Stripping & Production Turnover

Match-cure accuracy gives earlier, more confident release decisions—boosting daily output.

Lower Operational Cost = More Profit

By preventing over-curing, rework, and excessive labor, SensyCure™ minimizes waste and reduces the need for repeated cylinder testing.

Verified ASTM-Compliant Curing Process

Fully meets ASTM match cure requirements, helping producers pass inspections, audits, and DOT oversight with confidence.

Proven Strength Accuracy = Fewer Failures

Accurate temperature matching ensures more predictable concrete strength results, reducing low-break incidents and production interruptions.

Heavy Duty Rugged Build

Insulated, impact-resistant chamber with reinforced latches and heavy-duty wheels built for tough precast environments.

Automatic Temperature Matching

Wirelessly adjusts internal temperature to align with actual concrete core conditions..

Uniform Airflow Circulation

High-efficiency fan ensures even temperature distribution.

Dual Heating & Cooling System

Offers rapid temperature adjustments for precise curing control.

SensyCure™ Features

Unlock powerful automation and data intelligence:

-

Real-time Curing Insights

Live monitoring of internal cure-box performance

-

Smart Temperature Alerts

Auto notifications for temperature deviations and system faults.

-

Cure Cycle Visualization

Compare curing cycles and track temperature curves for consistent testing.

-

Full PDF reporting and CSV data exporting

Instant reporting for compliance, documentation, inspections, and audits.

-

Cloud Logging & Reporting

Unlimited cloud-based data with secure multi-device access.

-

Seamless Integration

Perfect for digital workflows—supports ERP, BIM, digital twins, and QC systems.

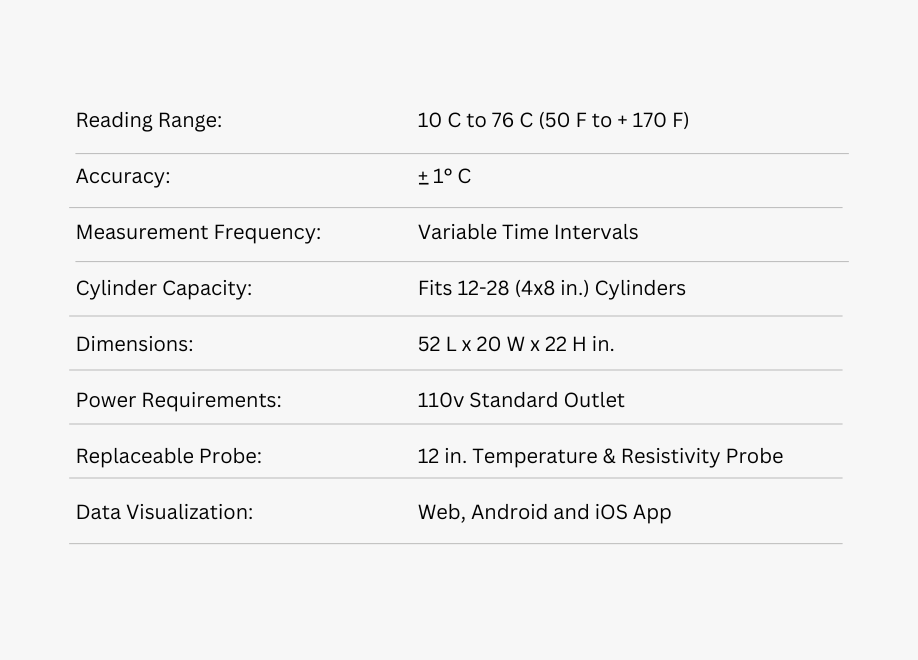

Technical Specifications

ASTM C31, C1074, AASHTO T-358, T-23

SensyCure™ Match-Cure System – FAQ

1. What is the SensyCure™ Match-Cure System?

SensyCure™ automatically replicates the exact temperature conditions of your concrete element to improve the accuracy and reliability of early-break test results.

2. How does match-cure technology improve accuracy?

By synchronizing the cure-box temperature with real concrete temperatures using live sensor data, SensyCure™ eliminates over- or under-curing and improves test reliability.

3. How many cylinders can SensyCure™ hold?

The system can hold 12–14 (6×12") cylinders or 28+ (4×8") cylinders.

4. Do I need to manually adjust the temperature?

No. SensyCure™ automatically adjusts temperature using built-in heating, cooling, and airflow control.

5. What sensors does SensyCure™ use?

SensyCure™ integrates with SensyCast™ sensors or any ASTM C1074-compliant temperature input.

6. Can I monitor curing data remotely?

Yes. SensyHub Cloud provides real-time charts, alerts, reports, and cylinder tracking via web and mobile.

7. Is SensyCure™ compliant with ASTM standards?

Yes. SensyCure™ supports ASTM C31, C192, C1074, and AASHTO T-23.

8. Can the unit heat and cool?

Yes. SensyCure™ features dual heating and cooling control for precise temperature following.

9. Is the system suitable for precast operations?

Yes. SensyCure™ enhances precast workflows with faster form turnover, predictable cycles, and reliable QC documentation.

10. What alerts does SensyCure™ provide?

The system sends alerts for temperature deviations, system warnings, sensor issues, and cure cycle completion.

11. Does SensyCure™ require water?

No. SensyCure™ is a dry, insulated curing system and does not require water baths.

12. How is the system powered?

SensyCure™ operates on 110V AC with low power consumption.

13. Can the system be used outdoors?

Yes. The rugged, insulated enclosure is designed for job-site and plant use.

14. Can I export reports or data?

Yes. SensyHub allows exporting PDFs, CSV logs, QC history, and cylinder documentation.

15. What maintenance does SensyCure™ require?

Minimal. Clean the fan intake, inspect sensors, and keep the chamber dry. No calibration needed.

16. How do I get support or training?

Your system includes onboarding, setup assistance, and full Sensytec support.